- #Calibrate cetus3d manual#

- #Calibrate cetus3d upgrade#

- #Calibrate cetus3d full#

- #Calibrate cetus3d software#

- #Calibrate cetus3d code#

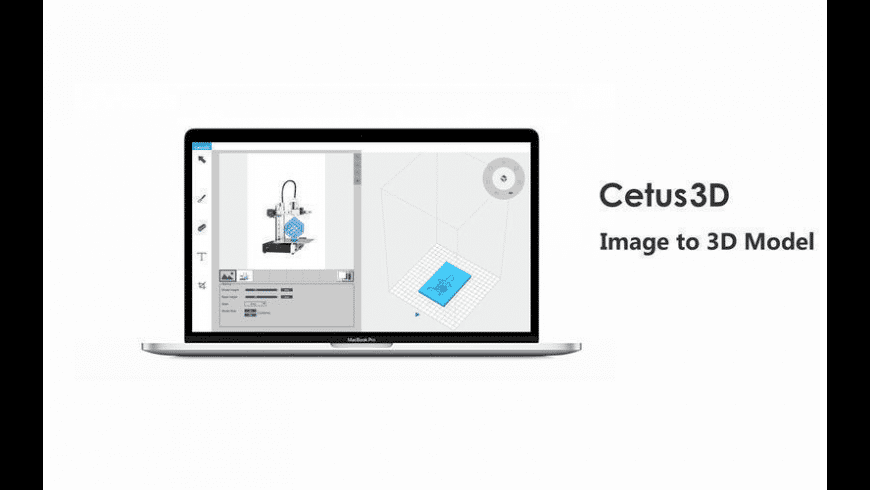

When a printed object is found to be deviating from its theoretical dimensions, we can use this method to correct it and achieve better precision. You can import any model from the library and you can either create one or download one from a website as well. The calibrating option is an essential one to reset the axes of the 3D printer after an object was printed.

I may try to collect a few in a database, contributions are welcomed. In order to produce G-code that succesfully prints on the Cetus, you still have to implement printer profiles for the various nozzles and layer thicknesses that you intend to use.Hovering your mouse over the various field will bring up their descriptions allowing for easy configuration.

UsageĬlick on Extensions > Post processing > Modify G-Code then select Cetus4Cura from Add a script. If you attempted to load some Start/End G-code before finding this script, make sure to remove it from preferences -> printers -> Machine Settings.

#Calibrate cetus3d full#

Controlling the position of the head after the print.ĭownload the script Cura4Cetus.py to the folder YOUR_CURA_INSTALL_PATH/cura/plugins/PostProcessingPlugin/scripts/ (please find the full path according to your platform).Reproducing sounds at the start of the job, when the hotend heating completes, and at the end of the job.Multiple materials may be 3D printed on the Cetus 3D printerabbaloo: Im told there are.

#Calibrate cetus3d upgrade#

#Calibrate cetus3d code#

b) the z-axis calibration code posted by cmeyer never worked for me. Perhaps the info below will help someone in the future: a) I used the start and end code from chrisevich (11) which worked nicely for me. A GUI allows selecting them with just a click and carries online documentation. I just wanted to thank everyone who contributed to this thread - it helped me tremendously when setting up my Cetus3D MkII with Cura. By doing so it introduces some of the functionalities implemented in UpStudio (such as beeping and purge line) and more.

#Calibrate cetus3d software#

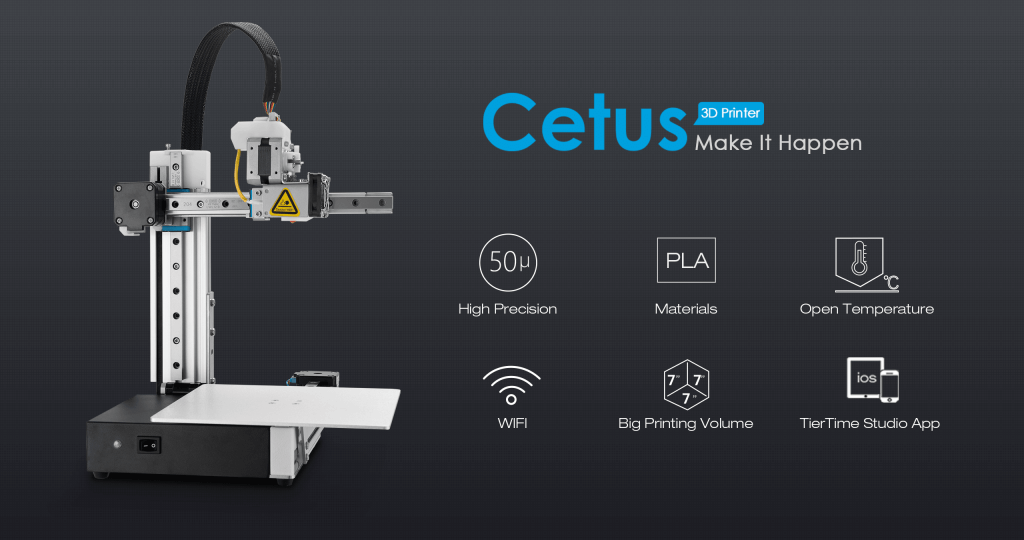

Experienced makers might prefer the latter to the original Tiertime UpStudio software due to its extra fine control of the slicing process.Ĭura4Cetus operates as a post processing script modifying the G-code produced by Cura. With a built-in sensor, Cetus2 is able to initialize with Fully Automatic Leveling and Z-Level Calibration to prepare for any task, saving you time and eliminating complicated setup.

#Calibrate cetus3d manual#

Manual leveling can be tedious and time-consuming, which can discourage people from getting started with 3D printing. This is a vital feature for combating these overheating issues.Cura4Cetus Cura + Cetus = 🤕 Cura + Cetus + Cura4Cetus = 😊Ĭura4Cetus is intended to ease and improve the usability of the Tiertime Cetus3D printer with the Ultimaker Cura slicer. Fully Automatic Leveling and Z-Level Calibration. For example, if you allow the software to adjust the printing speed for layers that take less than 15 seconds to print, the program will automatically slow down the printing speed for these small layers. If you click on “Edit Process Settings” and select the Speeds tab, you will see a section labeled “Speed Overrides.” This section is used to automatically slow down the printing speed for small layers to ensure they have enough time to cool and solidify before printing the next layer. Thankfully, Simplif圓D includes a very simple option to do exactly that. Even with a cooling fan, you may still need to decrease the printing speed for these small layers to ensure you provide enough time for the layer to solidify. This is particularly important for very small parts where each layer only requires a few seconds to print. If you are printing each layer very quickly, you might not allow enough time for the previous layer to properly cool before you are trying to deposit the next layer of hot plastic on top of it.

0 kommentar(er)

0 kommentar(er)